Sections of the site

Editor's Choice:

- How to unlock ariston washing machine

- Pros and cons of LED lighting

- Pulse relay: device and connection

- How to calculate the illumination of a room with LED lamps?

- Plastic box - do-it-yourself aesthetic view of electrical wiring

- Electricity consumption of a warm floor: electric and film

- Installing a pump in a well: how to properly install pumping equipment

- Electrician Toolkit Overview

- How to choose a water heater: the most complete list of evaluation criteria

- 1 acoustics on the example of Sven SPS-860 and Realtek ALC889 codec

Advertising

| Reversible magnetic starter connection diagram |

|

Electric motors are used in the vast majority for drive mechanisms and independent units. When a change in the direction of rotation of its shaft is required, a reversing starter is used for starting, the connection diagram of which is the subject of study by professionals and ordinary people.

How is the starter arranged and why is it needed?As can be logically determined from the name, this device is designed to start electric motors of various drive mechanisms and equipment. This is a specific equipment that is necessary for switching power purposes with large loads, both on direct and alternating current. The starter has a wider functionality than the basic contactor and, in addition to providing frequent starts and stops, can act as a protective barrier in case of overloads. In addition, reversing and non-reversing starters, for example, the PML series, have found their application in organizing remote control circuits, starting pumping, ventilation, crane units, air conditioners, etc. Any magnetic starter consists of the following main parts:

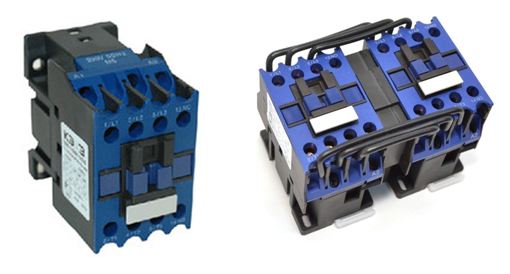

The difference between direct and reversing startersThe main difference between non-reversible and reversible starting devices is the connection diagram. The package is also changing. The direct type contactor is single, while the reversing contactor is block type, consisting of two straight lines combined in one housing. Visual differences between these two relays can be seen in the comparison of PML-1100 (left) and PML-1500 (right):

The connection diagram of the reversible magnetic starter of electric motors is divided into two main types:

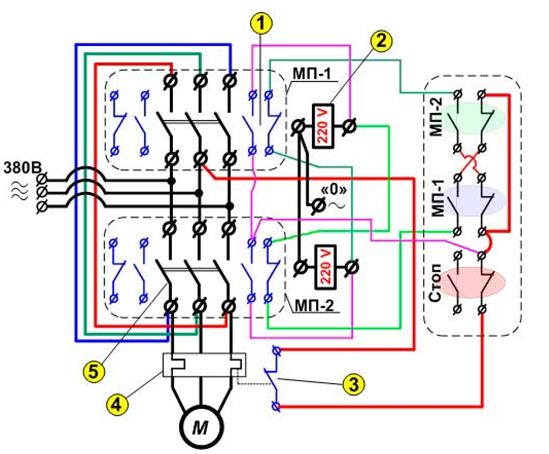

Type and operation of the reverse circuit for 220 VOn this wiring diagram, you can see the following main elements (indicated by numbers): To save on electricity bills, our readers recommend the Electricity Saving Box. Monthly payments will be 30-50% less than they were before using the saver. It removes the reactive component from the network, as a result of which the load and, as a result, the current consumption are reduced. Electrical appliances consume less electricity, reducing the cost of its payment.

In addition, alphanumeric designations are distinguished:

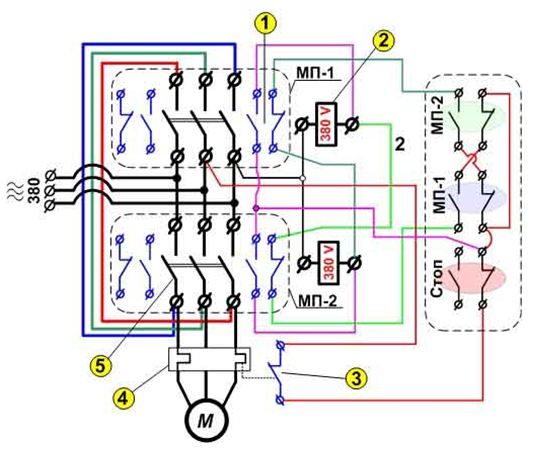

Operating principleAs you can see, three different phases from a 380 V network are connected to the power contacts of the starters. There is no designation in the above diagram, but in other cases you can find the symbols A, B, C or L1, L2, L3. A block connection is organized by a direct jumper of the central phases of the relay, as well as diagonal jumpers of the side phases (conditionally 1 phase MP-1 is connected to 3 phase MP-2, etc.). After that, the wires go to the electric motor M. At this interval, a thermal relay is connected to the circuit break. It monitors two of the three phases to cut off the power to the motor in the event of an overload. The control unit with start buttons is connected from one of the central phases to the break of the thermal relay, and the neutral wire (ground) from the coils. Protection against simultaneous activation of starters is organized by cross-connecting the contacts of the start / reverse buttons with the blocking contacts of the opposite contactor. When switched on from the forward stroke control unit, the contacts are closed to the first starter, which starts the engine. At the same time, the contacts of the second starter open, and the proper voltage is not supplied to the coil. The reverse is turned on after the engine is stopped by the Stop button, followed by pressing the reverse. Thus, we have on the coils the lateral phases changed in some places, which leads to the rotation of the engine in the opposite direction. The blocking of the first starter occurs according to a similar principle. Type and operation of the reverse circuit for 380 VHere we have, in fact, all the same elements that are used for PML at 220 V, but the starter coils are designed for a higher voltage (they have more turns). In addition, the difference from the previous scheme is the connection of the control unit not through one, but through two phases, without using a common zero.

Where else are reversing starters used?The scope of double starting relays is quite wide. It is not limited to electric motors alone. The need to change the direction of rotation or move the drive mechanisms may also arise in other cases. For example, each person has a water supply and heating system at home, where there is always a place for various shut-off valves. For industrial scale, with high flow rates, pipeline diameters, high accuracy of flow control, ordinary taps are indispensable. It uses electric gate valves, as well as a mechanical control system for the working body. The rotation of the disk or the movement of the valve occurs in different directions, which means that the use of reverse start-up schemes is justified.

Changing the direction of rotation of the engine, the actuators associated with it, is a rather popular procedure. In this case, power from a three-phase network occurs through an intermediate switching relay - a reversing magnetic starter type PML 1500 or any other. |

New

- Kievan Rus: education and history

- What vitamins are good for facial skin?

- Rudbeckia is spinous. Rudbeckia is a perennial. flower planting technology

- Secrets of losing weight by Ksenia Borodina What pills did Ksenia Borodina take for weight loss

- Kuriles: history with geography History of the disputed Kuril Islands

- Beer styles: porter and stout, lager and ale

- The optimal temperature for each stage of the distillation of moonshine and mash

- Rye malt and what can be done with it?

- How to make fortified wine at home

- How to make wine yeast at home, instructions for use